Projects

-

High Impact Product Improvement for better user experience

-

0-1 New Product Development: 6 axis Robotic 3D Printer

-

Academic Projects

-

Personal Projects

Nozzle Force Sensitive Auto Bed Leveling System for Carbon Fiber 3D Printers

Product & Project Management

Spearheaded a high-impact product improvement by identifying a critical customer pain point: high print-failure rates caused by inconsistent manual bed leveling. I defined the project scope, conducted cost analysis to ensure market feasibility, and managed the complete end-to-end 0-1 lifecycle. This required significant cross-functional collaboration and teamwork, coordinating between hardware, firmware, and testing efforts. The process ranged from initial R&D and requirements definition through final system validation and extensive reliability testing. This solution dramatically improved the user experience by creating a fully automated, force-sensitive system, which reduced the manual calibration effort to zero and eliminated a primary source of user frustration.

Technical Design & Implementation

I executed the core technical development, designing a custom strain gauge load cell optimized via FEA simulation. I engineered the custom PCB circuitry and developed the firmware from scratch, implementing complex signal processing for high-precision calibration. A key design constraint was to incorporate the solution into the existing system architecture without redesigning major components, a strategy that made implementation significantly cheaper and quicker for integration.

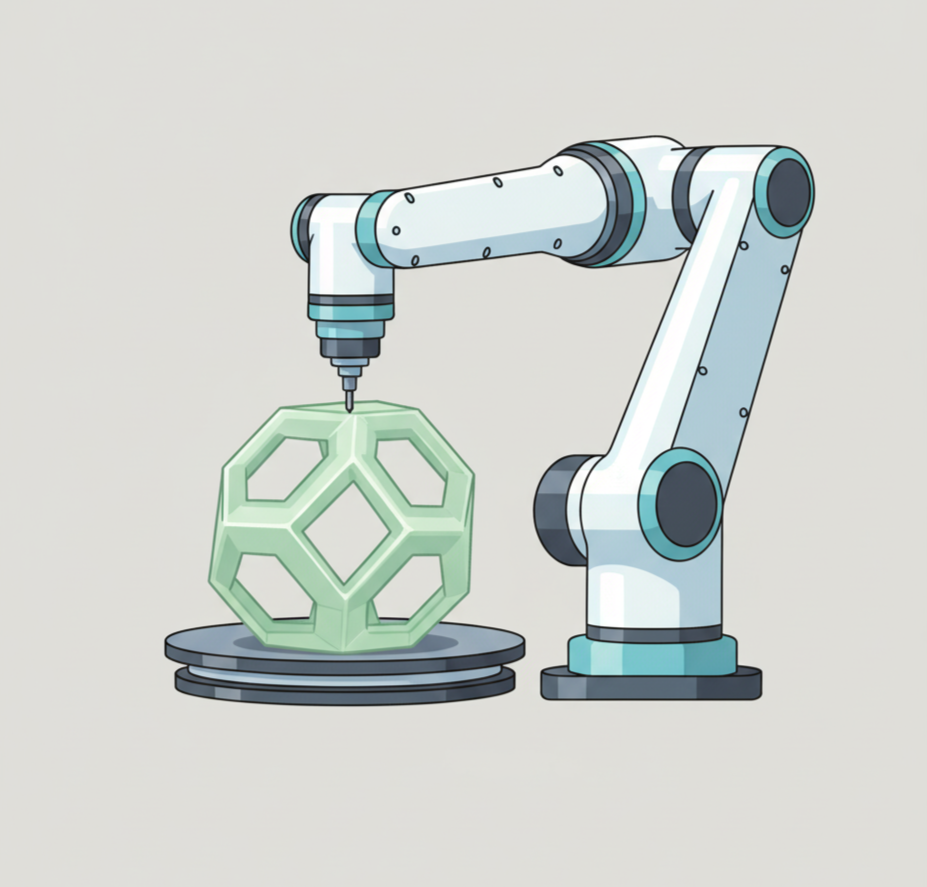

Concept to Prototype: Leading 0-1 Development of a 6-Axis Robotic 3D Printer

Product & Project Management

I led the complete 0-to-1 product development of a next-generation 6-axis robotic 3D printer, moving from initial concept to a fully functional prototype. I identified the market need for a system capable of printing complex geometries beyond the limitations of traditional 3-axis machines. I defined the product roadmap, conducted cost analysis by creating the Bill of Materials (BOM), and managed cross-functional efforts between mechanical design, electrical engineering, and firmware development. By applying Design for Manufacturing (DFM) principles early, I ensured the design was optimized for cost and assembly, culminating in the successful delivery and validation of the entire system.

Technical Design & Implementation

My hands-on technical leadership was crucial to the project's success. I designed the complete mechanical system and created the detailed CAD models. I also engineered the motor systems and all associated circuitry, including the PCB design. Following the design phase, I was responsible for the full prototype assembly, system configuration, firmware selection and tuning, and applying Design for Additive Manufacturing (DFAM) principles to optimize the components for printing.

Academic / Work Projects

PLC based production line automation retrofit into existing conveyor system

Designed and deployed a PLC-based control system to retrofit and automate an existing production conveyor line, giving system control and improving electrical efficiency.

3 DOF Robotic Arm (TRR Configuration) with Adaptive Gripper Prototype

Designed the arm kinematics and CAD model. Prototyped the adaptive gripper mechanism using 3D printing for rapid iteration and validation. Including circuit design, firmware and control logic.

Machine Vision based IOT connected Smart Parking Management System

Designed a parking solution leveraging Machine Vision and Image Processing for parking bay occupancy detection and IoT connectivity for real time reporting and navigation.

Overtake Prediction ADAS system in IPG Carmaker-On

Developed a high fidelity ADAS simulation model in IPG Carmaker environment for testing an Overtake Prediction System for Indian road conditions.

CANBUS Telematics system for Electric Motorcycles

Developed an embedded system to acquire and log critical vehicle data over the CANBUS protocol for remote telemetry and monitoring.

Portable, Cost Effective, Smart Weather station with IOT for farmers

Designed and built a low-cost, multi-sensor weather station, implementing IoT protocols for remote data acquisition.

Temperature Controlled Enclosure for ABS Printing in a Granular FDM 3D Printer

Designed and fabricated a heated enclosure to maintain precise thermal control for an FDM 3D printer. This project addressed material-specific challenges (like warping and layer adhesion in ABS), involved sensor integration, and ensured reliable, high-quality prints for engineering-grade materials.

Multi Face Recognition with Artificial Neural Networks for automated class attendance

Developed a real-time attendance system using Python and OpenCV, deploying a custom-trained Artificial Neural Network (ANN). The system accurately performed multi-face detection and recognition from a live video stream, demonstrating skills in machine learning, model training, and practical software implementation.

BSPD, Pre-Charge, and Discharge Circuits for Student Formula Team Car

Designed and fabricated a multi-layer PCB for the Brake System Plausibility Device and Pre-Charge/Discharge Safety Circuit (high-voltage safety), ensuring performance and strict competition compliance.

BMS Simulation in MATLAB Simulink

Built a Battery Management System (BMS) simulation model in MATLAB/Simulink to test and validate cell voltage balancing.

Comparative Study of Coil Shapes for Electric Vehicle Resonant Wireless Power Transfer System

Research Paper presented at PEIS 2024, National Institute of Technology

Personal Projects

IOT Based Gate/Garage Automation

Implemented a remotely controllable IoT solution integrated with Alexa, Google Home, and smartwatches, focusing on connectivity, access control, and voice command logic.

Custom Drone Build

Designed and built a custom drone, including flight controller firmware programming.

Custom built a FDM 3D Printer

Built and calibrated an FDM 3D Printer from components, integrating advanced features like filament runout sensing, live monitoring camera, and auto bed leveling.

Vehicle Electronics - OBD Diagnosis and ECU Coding

Performed advanced diagnostics and data logging using On-Board Diagnostics (OBD) tools, and executed ECU coding to customize and enable specific vehicle features.

Customized auxiliary light mounts for SUVs - CAD design and fabrication

Designed and CAD modelled structurally optimized mounts, generating detailed manufacturing drawings for production via laser cutting and sheet metal fabrication.

Designed Modular, Ergonomic and adaptable Handle Bar Risers for Motorcycles

CAD Designed adjustable and modular handlebar risers for motorcycles, incorporating ergonomics and modularity into the design.

IOT enabled water pump automation system

Developed and built an automated pump control system with a mobile app dashboard and real-time monitoring for status and water level.

Automotive Enthusiast / Weekend Builder

Regularly engage in advanced vehicle modification, custom diagnostics, and performance system work as a continuous engineering hobbyist.

Home Infrastructure & Power Systems

Wired and installed a specialized home electrical infrastructure, including a high-power servo stabilizer and the complete wiring installation for a home elevator control system.